LCD Shutterglasses

Rainbow Adapter

Usage

Construction

Circuit Description

For the official kit from

OmberTech

By Kevin Koster

2018

Contents

|

Introduction

|

|

|

|

Usage

|

|

|

|

Construction

|

|

|

|

Parts List

|

|

|

|

Resistors and Diodes

|

|

|

|

Integrated Circuits

|

|

|

|

MKT Capacitors

|

|

|

|

Electrolytic Capacitors and

LED

|

|

|

|

Switches

|

|

|

|

Wires

|

|

|

|

Enclosure Assembly

|

|

|

|

Modifying Wireless

Shutterglasses

|

|

|

|

Theory

|

|

|

|

LCD Elements

|

|

|

|

Circuit Description

|

|

|

The rainbow adapter for LCD

shutterglasses uniquely exploits a refractive effect exhibited in liquid

crystal display "elements" when fading out from their opaque

state. This allows a rainbow of colours to be viewed surrounding reflective

objects.

The following page describes usage of

the adapter, then we move on to a step-by-step description of how to

construct the adapter kit, as well as modify an unwanted pair of active 3D

shutterglasses for use with it. Then finally, we look at exactly what

electronics are required in order to put rainbows in your eyes.

With four AA batteries fitting snugly

in the battery holder, a simple flick of the "Power" switch while

the "Boost" switch remains off will begin powering the

shutterglasses with the alternating drive signal that produces the

refractive "rainbow" effect. Within thirty seconds a halo of

multicoloured bands should be visible around lights, windows, and white or

reflective objects. After about a minute, the effect should have built up

fully.

The effect is most visible in more

dimly lit areas out of direct sunlight, or outdoors at sunrise or sunset.

Hold a piece of white paper in the sunlight shining through a window to see

rainbow coloured images of it "floating" above on either side.

When outdoors, face away from the sun to view the reflected light to best

effect, remember never to look directly at the sun.

When Boost mode is enabled, the drive

voltage to the shutterglasses is increased and the effect is made brighter

and more vivid. However this may cause instability in the circuit, and in

any case the effect will fade and become less defined shortly after this

mode is enabled. Turning Boost mode off again returns to regular

performance.

Some faint flickering will be visible

while the glasses rapidly fade in and out. Take a break if this begins to

cause headaches or nausea.

The adapter can connect to most wired

3D shutterglasses designed for use with PC 3D graphics adapters or TVs

when they are equipped with a 3.5mm stereo plug. Some models may produce

the effect while some may not, the only way to know is to give them a try.

Wireless adapters require modification

to connect wires from the adapter circuit directly to the LCD "lens"

elements. This is described in the following section.

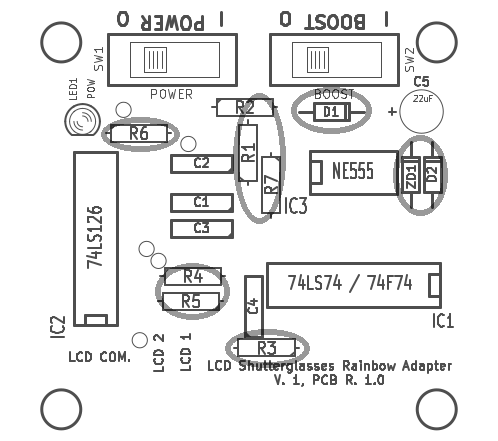

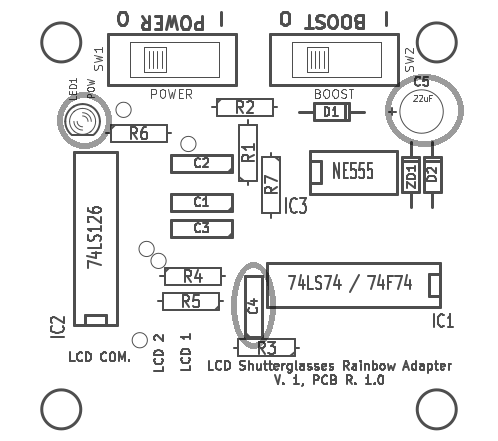

If you have purchased the rainbow

adapter kit from OmberTech, you are likely reading this in the company of

an assorted bag of bits (described more exactly in Figure 1) that you hope

to turn into the driver for your new rainbow tinted glasses. This chapter

will guide you though step-by-step in the fulfillment of this goal. So grab

your soldering iron and let's get started!

This kit doesn't use any CMOS devices,

so no special static precautions are required when handling the components.

|

Part

|

QTY

|

Identifiers

|

Marking

|

|

100nF MKT Cap.

|

3

|

C1, C2, C3

|

104J100

|

|

4.7uF Electrolytic Cap.

|

1

|

C4

|

4.7uF

|

|

22uF Electrolytic Cap.

|

1

|

C5

|

22uF

|

|

1N4148 Silicon Diode

|

2

|

D1, D2

|

1N4148

|

|

4.7V Zener Diode

|

1

|

ZD1

|

TZX 4V7 C

|

|

3mm LED

|

1

|

LED1

|

|

|

74LS74 Flip-Flop IC

|

1

|

IC1

|

SN74LS74AN

|

|

74LS126 3-State Buffer IC

|

1

|

IC2

|

SN74LS126AN

|

|

555 Timer IC

|

1

|

IC3

|

SE555P

|

|

47ohm Resistor

|

1

|

R7

|

Yel, Ppl, Blk

|

|

1.2Kohm Resistor

|

1

|

R3

|

Brn, Red, Red

|

|

2.2Kohm Resistor

|

2

|

R4, R5

|

Red, Red, Blk, Brn (Green body)

|

|

3.3Kohm Resistor

|

1

|

R6

|

Ong, Ong, Red

|

|

56Kohm Resistor

|

1

|

R2

|

Grn, Blu, Blk, Red, Brn (Green body)

|

|

100Kohm Resistor

|

1

|

R1

|

Brn, Blk, Yel

|

|

DPDT PCB-Mount Switch

|

2

|

SW1, SW2

|

|

|

|

|

|

|

|

3-Way Ribbon Cable

|

1

|

|

|

|

4xAA Battery Holder

|

1

|

|

|

|

50x50mm Circuit Board

|

1

|

|

V. 1, PCB R. 1.0

|

We begin with the resistors and diodes.

Resistor values are shown in Table 2 below. Ensure that the black band at

the end of the diodes matches the corresponding mark on the silkscreen

image.

|

Identifier

|

Value

|

Marking

|

|

R1

|

100K

|

Brn, Blk, Yel

|

|

R2

|

56K

|

Grn, Blu, Blk, Red, Brn (Green body)

|

|

R3

|

1K2

|

Brn, Red, Red

|

|

R4, R5

|

2K2

|

Red, Red, Blk, Brn (Green body)

|

|

R6

|

3K3

|

Ong, Ong, Red

|

|

R7

|

47R

|

Yel, Ppl, Blk

|

Table 2,

Resistor Values.

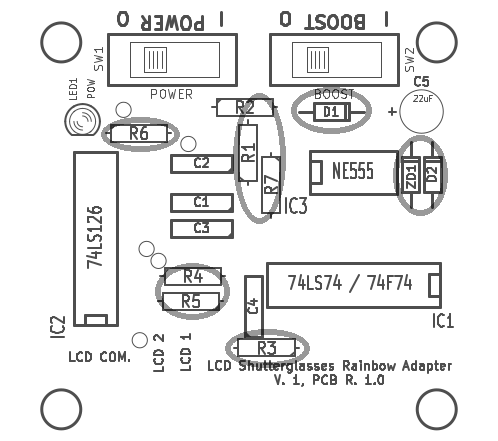

The ICs are now soldered into place,

watching that the notch or round mark on the their top matches the mark on

the silkscreen image.

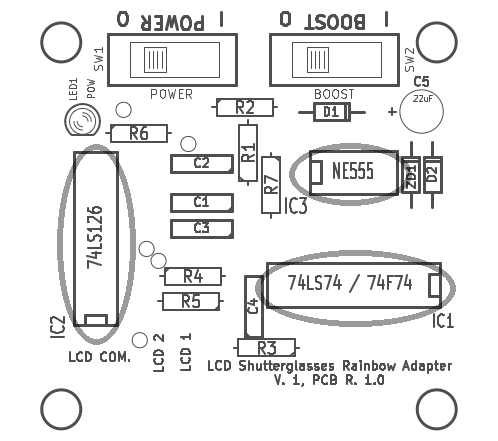

These little grey blocks of capacitance

are all lined up in the middle of the board, time to plop them on.

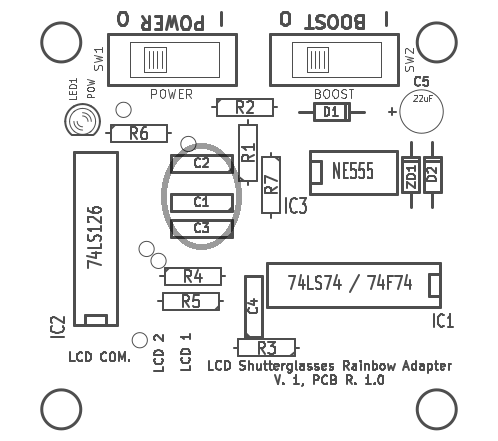

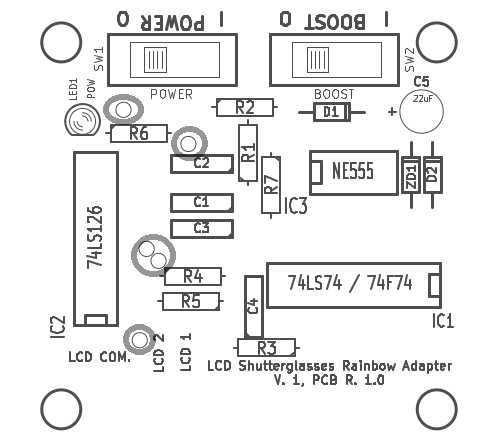

The remaining capacitors and the power

LED now get their turn. There's no mark indicating the orientation of C4 on

the silkscreen, but it should be orientated with the negative side (marked

by the stripe and the shorter lead) closest to the center of the board. C5

is orientated with negative facing outwards from the board, as indicated by

the little "+" symbol on the silkscreen. Also watch that the

notch on the body of the LED (and the shorter lead) match the image on the

silkscreen.

C4 can be bent down over R4 and R5

before soldering, and the same done to C5 on top of ZD1 and D2. If using

the optional second board mounted above for protection, bend the LED

sideways as well so that it sticks out the side and is visible when

everything is assembled.

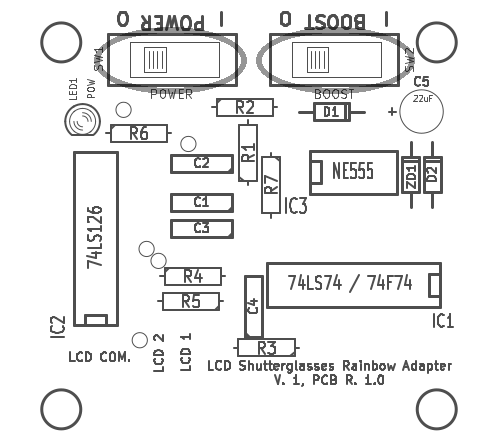

The only components missing from the

board should now be the switches. Try to get the "legs" of the

switches resting flat against the board so that minimal stress is put on

the connections during use, and also to make sure that they don't end up

too high if you're using the optional second board for protection.

Wire connections are brought in from

the top of the board and fed through holes in order to prevent strain from

twisting at the solder joints. The grey three-way ribbon cable for

connecting with the glasses is parted and the individual wires can be

pulled through the holes with their insulation using pliers. The Power

wires from the battery holder turned out to be a little thick for this, so

only the core wires may fit through the holes, stripped of their insulation.

Once through to the solder side of the

board, the wires are soldered to the long pads described by writing on the

silkscreen or copper layer. The "LCD COM." pad is broken into

two, and the wire must be soldered over both of these pads.

If you're using wired glasses with the

adapter, you can solder a 3.5mm socket onto the end of the ribbon cable to

connect with the plug from the glasses. Make sure to connect the "LCD

COM." wire with the base of the 3.5mm plug, and the LCD 1/2 wires to

either the middle or the tip with no preference to which.

Final Checks:

With the circuit board completed, now

is the time to check over your work for any of those pesky components that

like to hop into the wrong position, or spin themselves the wrong way

round, while you're not looking. While you're there, check the bottom of

the board for any missed or bridged solder joints.

If you're happy with the board on its

own, or you have your own case, you can now start using your wired glasses

with the rainbow adapter, or move over to the section on modifying wireless

glasses to connect them to it.

If you bought the optional second board

to mount above the adapter circuitry for protection, now you can install it

using the nuts, bolts, and plastic spacers supplied.

The outer screw holes in the battery

holder are aligned with the holes at the switch end of the adapter board,

and the bolts run through from the battery compartment side. Drop the

spacers onto the bolts and do the same with the bolts at the other end

before installing the second board with the notched end above the switches

to allow easy access. Add the nuts to the end of the bolts and tighten the

bolts with a flat head screwdriver while gripping the nuts with pliers.

Additional protection might be achieved by wrapping the sides in electrical

tape, while making sure to leave the power LED visible.

Results with different models of

shutterglasses have been mixed. While the old PC wired glasses optionally

offered for sale with the adapters, and a pair of HiSense brand wireless

glasses for 3D TVs from 2011 have worked, a pair of SamSung 3D TV glasses

from 2013 failed to work with the adapter. Although these latter glasses

briefly showed the effect while unplugging them from the circuit, no timing

arrangement in the circuit has succeeded in making it visible for any

length of time. In the end it just comes down to "try it and see".

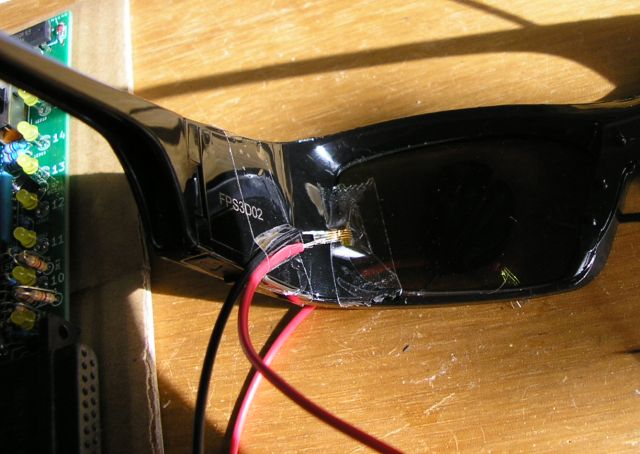

To attempt such a try, the first step

is to break into the circuitry that controls the LCD "lenses" and

cut the connections before wiring them directly to the adapter. The

following pictures show disassembling the Hisense brand glasses, model

FPS3D02.

First remove any screws that are

present. Look around the hinges.

Next the plastic clips that hold the

glasses together will have to be prised apart. Use a flat head screwdriver

to slip into the gap and lever the front apart from the back. The strength

of the clips can vary and it may be impossible to separate the halves

without damaging the plastic, but try hard to avoid putting pressure on the

glass it can easily crack. The middle is the most difficult part.

Once inside, the lenses on modern

glasses seem often to be connected using a flexible PCB. On the SamSung

glasses it was easy to solder the wires onto the solder pads connecting the

lenses to the flex, then the control board was cut off to prevent it

interfering. On the HiSense glasses, the wires had to be carefully soldered

to the contacts at the end of the flex where it was meant to fit into a

connector on the control board.

SamSung Glasses

Hisense Glasses

Remember that the LCD 1/2 wires can be

interchanged, but the LCD COM. wire must be the one that connects to both

of the lenses. Polarity is not important.

Once all the wiring is done, the case

can be pressed back as well as is possible (it may need to be glued if the

wire pushes the halves too far apart, or the clips have all broken). Then

the screws are put back, and with a bit of luck you can put the glasses on

and let them bring some brand new colour into your world.

The "lenses" in the LCD

Shutterglasses are equivalent to single pixels in a monochrome Liquid

Crystal Display, or single elements of a 7-segment numeric display. The "D"

in "LCD Shutterglasses" is therefore out of place because there

is nothing that can really be displayed by glasses with lenses that in

normal use can only be transparent or opaque.

From an electrical perspective the

elements themselves act as capacitors. When charged, the Liquid Crystal

molecules align to straighten out a twist in their structure that otherwise

rotates the polarisation of light passing through. By placing polarising

filters either side of the crystals, when the polarisation of the light is

opposite to the outer filter, no light can get through at all. Depending on

the filter this can happen in either the charged or discharged state of the

LCD element. Most commonly it is in the charged state, so when a signal is

applied the element becomes opaque.

It would seem that this signal might

simply be a fixed voltage difference, but to complicate matters LCD

elements perform best and live longest when the polarity of their charge is

constantly changed. The signal therefore needs to be rapidly alternating

from High to Low in opposite states across the LCD element's two electrical

connections. Then it appears opaque until the element is shorted so that it

can allow light to pass through once more.

In this circuit we add one more input

state for this capacitive LCD element, which discharges it slowly so that

it fades out rather than being shorted out and made immediately

transparent. A possible explanation for the resulting effect is that the

slow discharge results in the liquid crystal molecules lingering in a

partially twisted state, thereby partially rotating the polarisation of the

light traveling through. The wavelength of the light influences the degree

of rotation that takes place, so the different colours of light become

visible in bands, as in a rainbow.

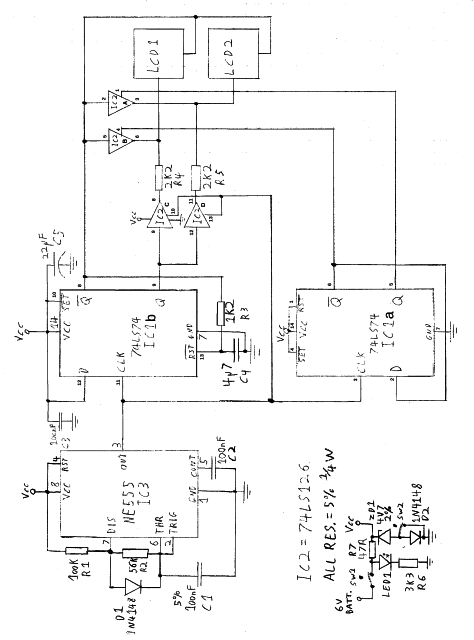

Figure 1, Schematic.

IC3 is that old favourite the 555

timer, here configured with D1 ensuring a longer On time than Off time by

allowing C1 to bypass R2 when it charges while the output is High.

At the same time as this output is

High, IC2c/d (74LS126) are enabled, allowing the non-inverted output of the

IC1b (74LS74) Flip-Flop to be applied to R4 and R5. When the clock signal

from IC3 goes from Low to High, the Flip-Flop output likewise goes Low to

High as well. But at the same time C4 begins to discharge via R3, connected

to the Flip-Flop's inverted output, and eventually causes it to reset,

bringing the non-inverted output back Low again.

This oscillation alternately charges

the active LCD element because the opposite states of the inverted and

non-inverted Flip-Flop outputs are applied to it.

Meanwhile, the inactive element is

shorted out by either IC2a or IC2b. These force both of the LCD connections

to an equal voltage and thereby discharge its capacitance. The active

element is alternated on each clock cycle by Flip-Flop IC1a which toggles

the Enable inputs of the IC2a/b 3-state buffers.

The connection of the Enable inputs of

the other 3-State buffers IC2c/d to the clock signal allows the active LCD

element to be discharged slowly for the Low period of the clock waveform

(set by R2) when all the buffers on one of its connections are in 3-State

mode. This fades out from the charged, opaque, state that it was in during

the preceeding High period of the clock waveform. The complete resulting

output waveform is shown in Figure 2.

Finally, the effect was found only to

work at drive lower voltages to the LCD elements, but with an increased

brilliance when the circuit supply voltage was quickly raised from around

4.75V to above 5V, before fading out. The power regulation part of the

circuit, shown in the bottom left of the schematic, makes sure that the

normal supply voltage is set for optimal performance by using ZD1 to keep

it within 2% of 4.7V. SW2 effectively switches a silicon diode in series

with ZD1's path to GND, increasing the voltage across it, and therefore the

circuit supply voltage, by at most about 0.7V. This provides the "Boost"

functionality, but unfortunately also introduced circuit instability with

some 74LS74 ICs. The power LED is connected to the unregulated part of the

supply to prevent unneeded power dissipation across R7.

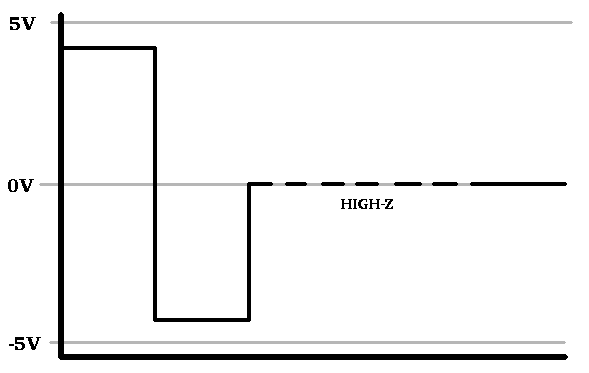

Figure 2,

Output Waveform. Shows voltage measured over LCD

COM. and either LCD 1 or LCD 2 output, with no LCD element connected.

Begins at the rising edge of the clock cycle. The dotted line indicates

that both output buffers on the LCD output are in 3-State mode.